Material processing in automotive, specifically laser cutting has come a long way in the last 30 years. The market requirements for improved strength, weight savings, and lower costs drive the need for manufacturers to use materials such as high strength steel and aluminum. Hot press hardened steels (PHS), generalized as high strength, include many different trade names. The key aspect to gaining toughness is through heating of the material in the stamping press, forming the part and then quenching to achieve hardening of the steel while forming the stamped shape. In a traditional automotive stamping, a part goes through various stages of die forming with a final trimming die to form the metal to the net shape. PHS parts are hard and nearly impossible to trim in a die, and require a machining process to create the correct net shape. The most effective and popular choice for trimming PHS is through laser cutting. There are two primary means of laser cutting including robotic and CNC laser cutting.

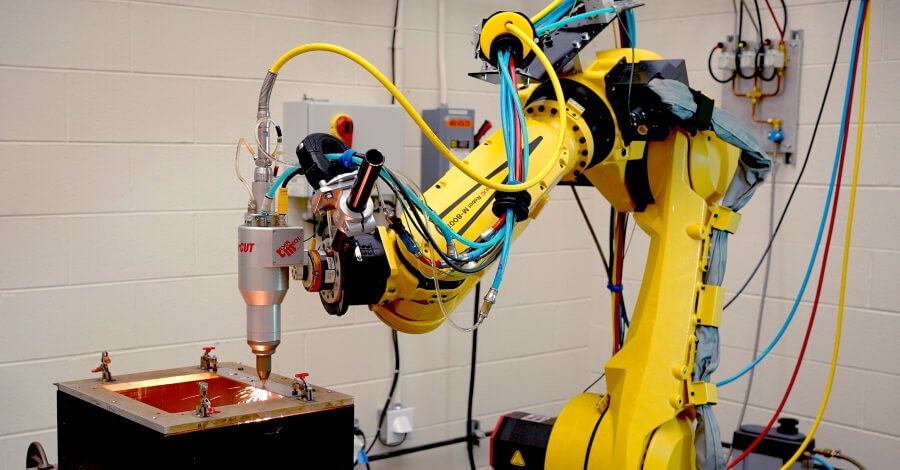

Robotic cutting has evolved with improved robotic motion performance by accurate mathematical models of the robot mechanism and the improvements in the controller’s servo performance and path planning. This has allowed robotic laser work cells to offer a competitive cost-per-interchange part when compared to a CNC cutting operation. This is especially true when processing automotive components that have a varied shape and require 5+ axes of motion to process the 3D parts as compared to traditional CNCs used for sheet or plate processing. Today’s six-axis robots such as the FANUC M-20iB/25 offer the best robotic accuracy and speeds but do not equal the accuracy of a purpose-built CNC. Manufacturers need to consider the tradeoffs of slightly less accuracy of a robot but with much greater throughput than a CNC. Robotic laser cutting capabilities offer improved density of the laser processing and how many ‘laser heads’ can be put on the part at the same time. There is more… New developments in robotic cutting continue to close the gap on path accuracy with speed, taking the robotic to CNC performance levels and with higher throughput.